Bending Sheet Metal Problems Formula

You can find your bend allowance with the following formula.

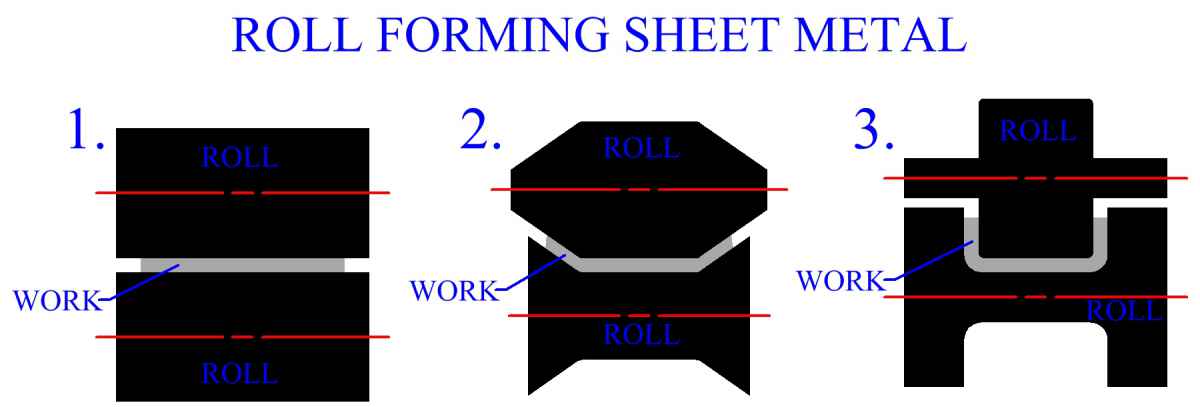

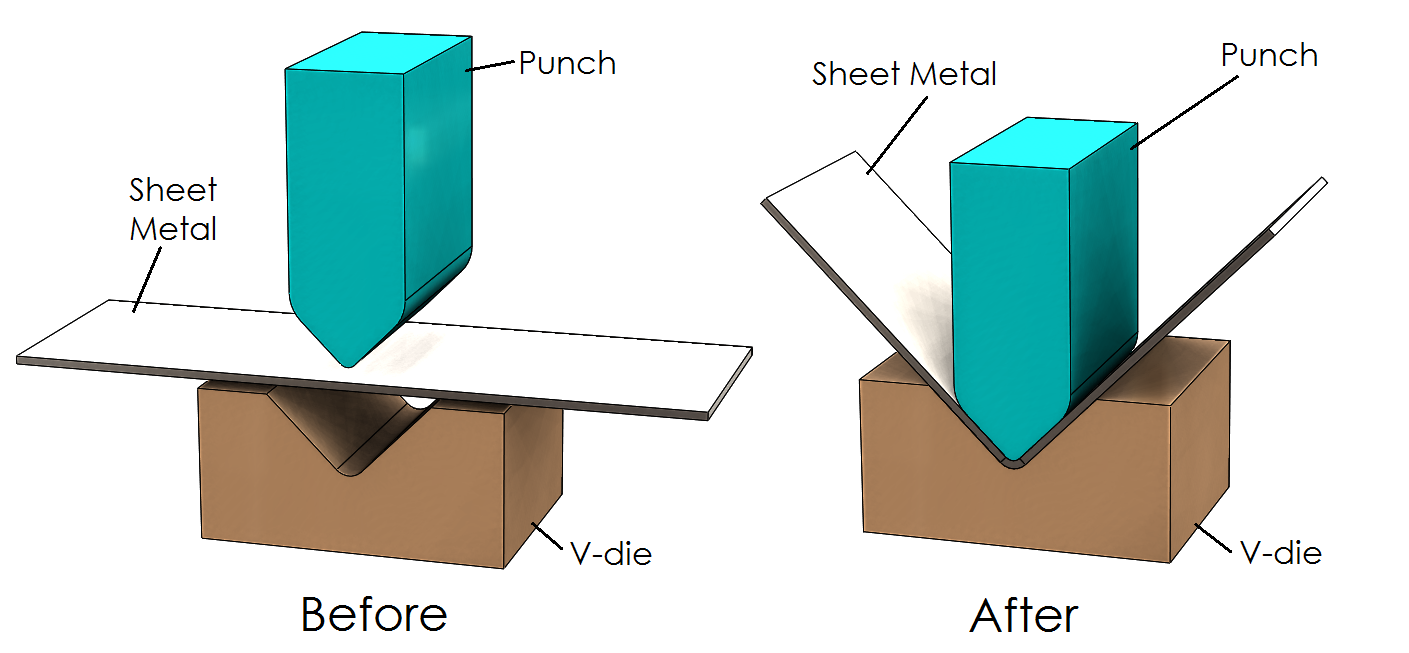

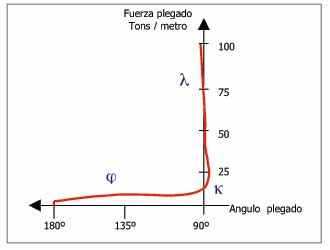

Bending sheet metal problems formula. Bending is a manufacturing process that produces a v shape u shape or channel shape along a straight axis in ductile materials most commonly sheet metal. This is done through the application of force on a workpiece. The force must exceed the material s yield strength to achieve a plastic deformation. Material thickness mt the gauge of the material in decimal form.

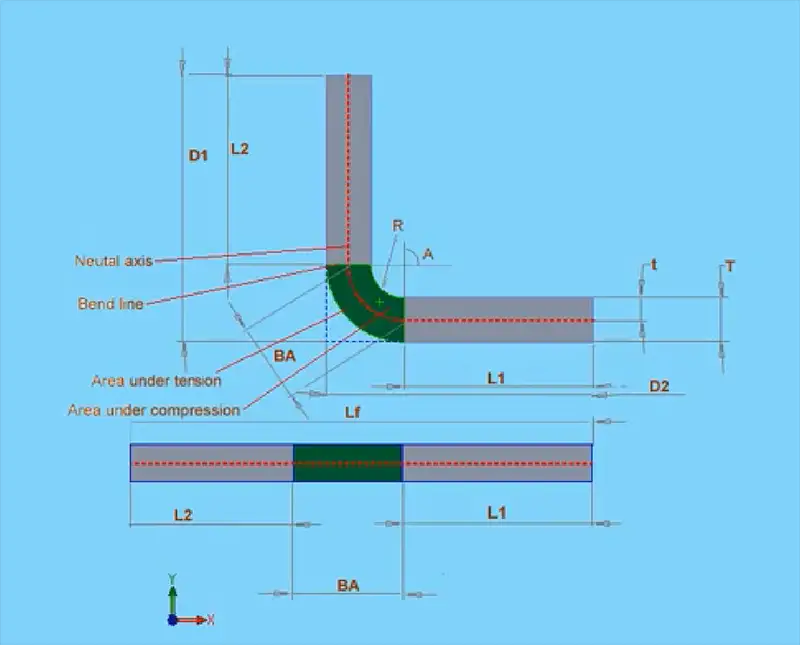

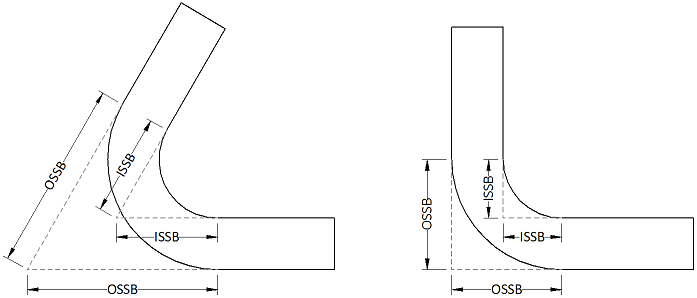

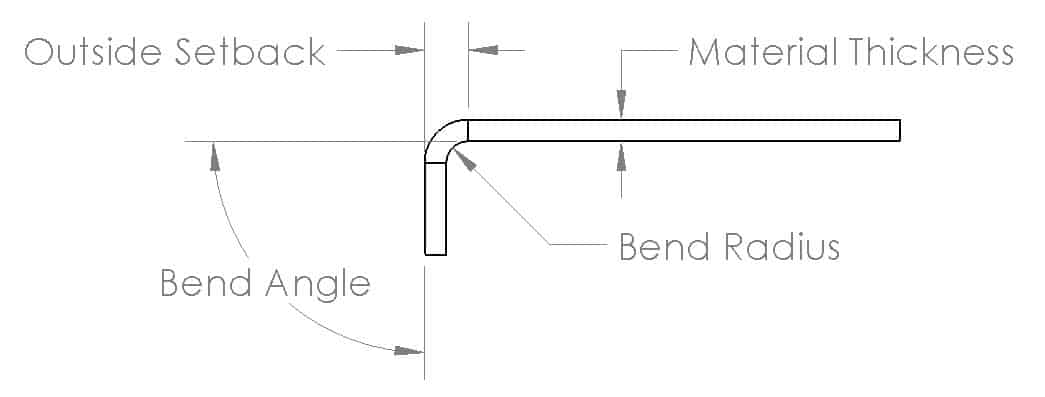

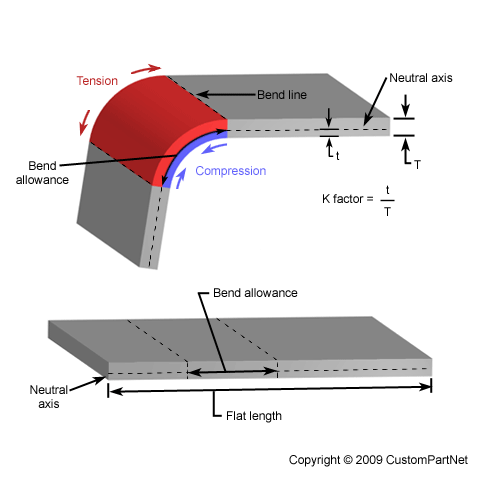

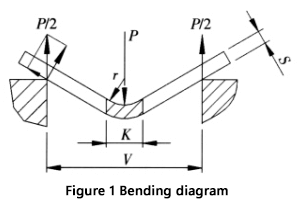

Where ossb is the outside setback. The material thickness will be measured in decimal form not by the gauge number. You will need to know your material thickness mt the bend angle b the inside radius ir and the k factor k. Where a is the bending angle t is the sheet thickness and r is the bending radius.

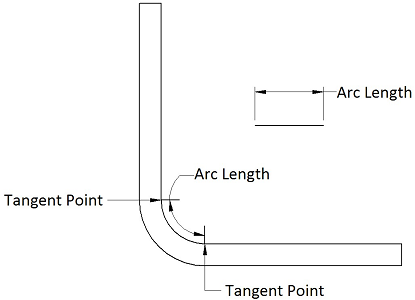

Commonly used equipment include box and pan brakes brake presses and other specialized machine presses typical products that are made like this are boxes such as electrical enclosures and rectangular ductwork. The bend allowance formula takes into account the geometries of bending and the properties of your metal to determine the bend allowance. π 180 x b x ir k x mt bend allowance ba where b is the angle complementary to your desired bend angle 1 to 180 degrees mt is the thickness of the material ir is the inside radius and k is the k factor. Bend deduction bd the amount removed from the sum of the two flange lengths to obtain a flat pattern.

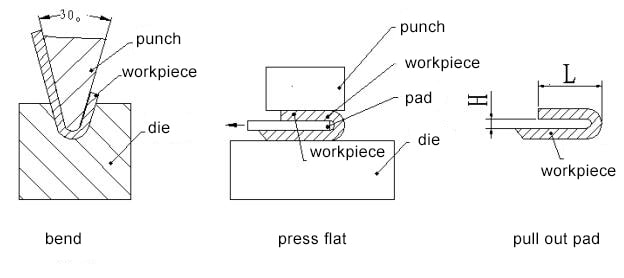

Bend allowance ba the amount of added to the sum of the two leg lengths to obtain the flat pattern length. Get to know them better to learn advance concept easily. Minimum bending radius is a function of the. When h is lower than 5t one time forming is enough.

6 t 2 edge distance of v groove 1 8 t 2 t see the picture. Bending and forming of the metal sheet are carried out on a plate bending machine. Ossb is defined as illustrated in figure 5 for different bending angles and can be calculated using the equation below. As explained in my first post the bend deduction can be calculated using the following equation.

Bend angle b the inside angle between the two legs or flanges of a bend. Bending is one of the most common sheet metal fabrication operations. Bend line shift bls the distance from the outside mold line to the original bend line on the flat pattern this is used to calculate the backstop location when working off of a flat pattern. 2 the main factors that affect the minimum z bending value are the width of v groove and the distance from the center of the v groove to the edge.