Bending Spring Steel Sheet

Compared to carbon steel for the same thickness of stainless steel the bending angle is larger special attention should be paid to this point otherwise the bending crack will appear affecting the strength of the workpiece.

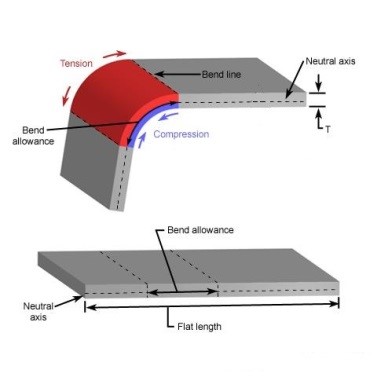

Bending spring steel sheet. Bending is one of the most common sheet metal fabrication operations. After a bending operation residual stresses will cause the sheet metal to spring back slightly. Determine your minimum bend by measuring the distance from your closest feature i e. The bending angle is the beginning angle to which the operator overbends so that the metal springs back to the desired bent angle.

Springback is ever present in sheet metal forming. Choose a bend radius that matches your minimum bend. This is done through the application of force on a workpiece. Here s how it s done.

Blue tempered and polished spring steel. To a press brake operator a bending angle is different from a bent angle and it all has to do with that ever present forming variable. Shaping a spring to it s desired shape. Spring steels are known for their high yield strength which allows objects made of spring steel to return to their original shape after bending and forming.

Due to this elastic recovery it is necessary to over bend the sheet a precise amount to acheive the desired bend radius and bend angle. The final bend radius and bend angle can be approximated from the sheet thickness k factor material yield strength and modulus of elasticity and the initial bend angle and bend radius. Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape. Tempered spring steel is commonly referred to as high carbon steel and is useful for a number of applications including use in springs and steel tapes.

Cooling down slowly it will not re hard and you can treat it as any other common steel. A cutout or the edge of your flange to your bend. If you want to bend it you have to have to heat it to red glowing when it will loose its hardness. If you have any questions or want to discuss your design contact us.

Our offerings also include. 002 through 125 widths in stock. The force must exceed the material s yield strength to achieve a plastic deformation. 125 through 24 scaleless tempered.