Bending Stiffness Of Sheet Metal

Use one of the many free online moment of inertia calculators like this one to see how increasing the height of the beam will have an exponential effect on increasing the stiffness of the beam.

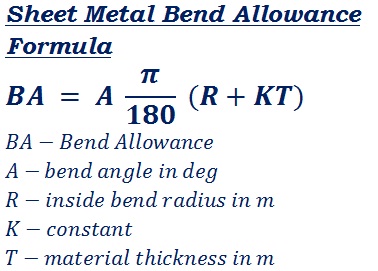

Bending stiffness of sheet metal. The moment of inertia affects the beam s ability to resist flexing. Strain hardening which occurs during the structuring process also improves the rigidity of the product. The solution is to have a radius on the tool that you ll be using to bend the metal. In addition to creating a desired geometric form bending is also used to impart strength and stiffness to sheet metal to change a part s moment of inertia for cosmetic appearance and to eliminate sharp edges.

Another way of strengthening the sheet metal is by punching holes and slots. Sheet metal edge bending. 3 d structured sheet was used for. The metal in the areas where holes and slots are punched gets stretched and become more tensile which gives more structural rigidity to the sheet metal.

All materials have some degree of elasticity including metal which is highly known for its stiffness. The 3 d structure enhances the mechanical properties of components primarily by increasing bending stiffness because of increased inertia the higher the structure the stiffer the sheet. These methods will give sheet metal the rigidity you need to use it in a structural or semi structural application. How large of a bend you put in the metal depends on the application and fitment of the piece.

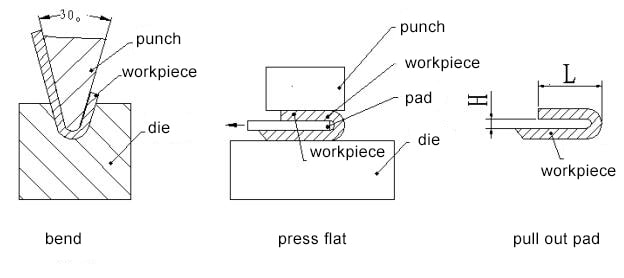

Structured sheet is thin sheet metal with a 3 d structure. And this site helps provide a pictorial view of the load s upon a beam depending. Well known structured sheet applications include corrugated sheets for roofs and facades. This is done through the application of force on a workpiece.

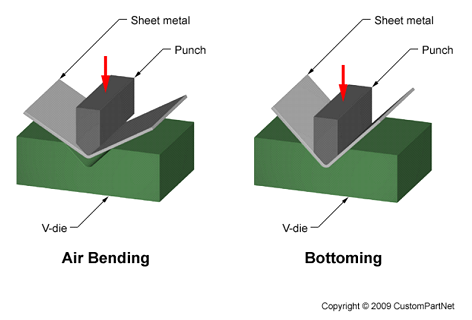

To neutralize aluminum being one third the stiffness of steel an aluminum part must be made 44 percent thicker than the steel part. Following a plastic deformation that we make to bend the metal an elastic recovery followed once we remove the load causing the metal to attempt moving back in place. For most operations however bending will produce essentially no change in the thickness of the sheet metal. First the molecular density is greater on the inside of the bend than it is on the outer surface that is being stretched.

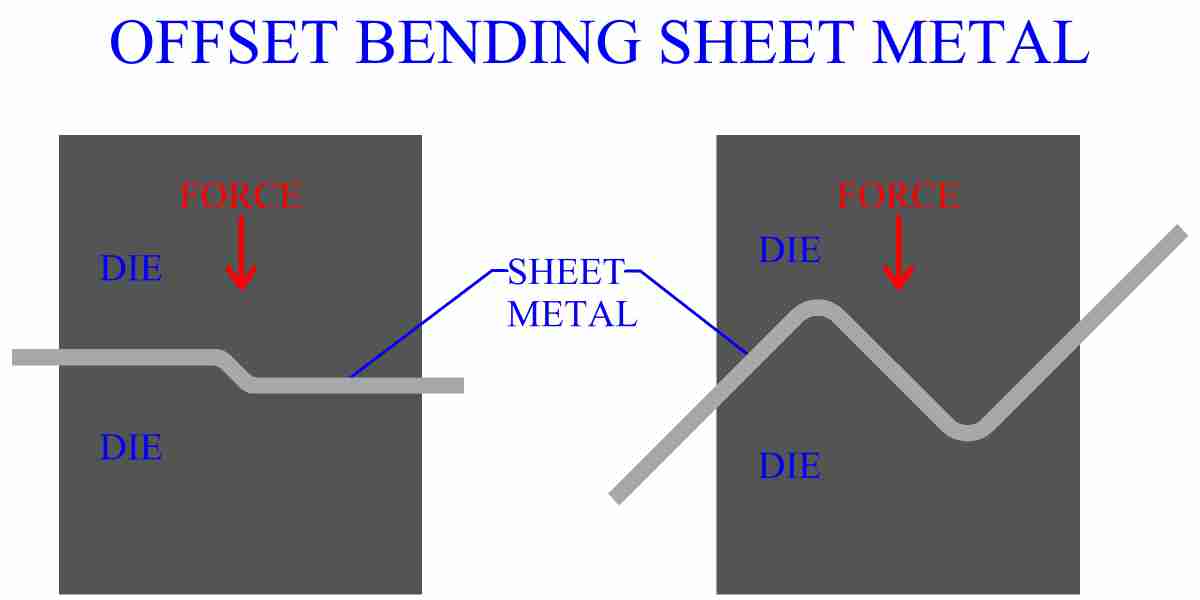

This happens for two reasons. To define the bend region and reduce the force required to bend a part out of sheet metal down to something you can handle without a brake press slots can be cut at the bending line to selectively. Sheet metal should be bent at the minimum bend radius possible. Bending is one of the most common sheet metal fabrication operations.

Why does sheet metal spring back. Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape. Even on malleable materials you can end up cracking the metal at the bend or weakening it to the point where it ll break with minimal force. Even with this increased thickness there is a potential for weight savings since aluminum is one third the density of steel.