Bending Test Of Sheet Metal Forming

Cutting and related operations quiz key.

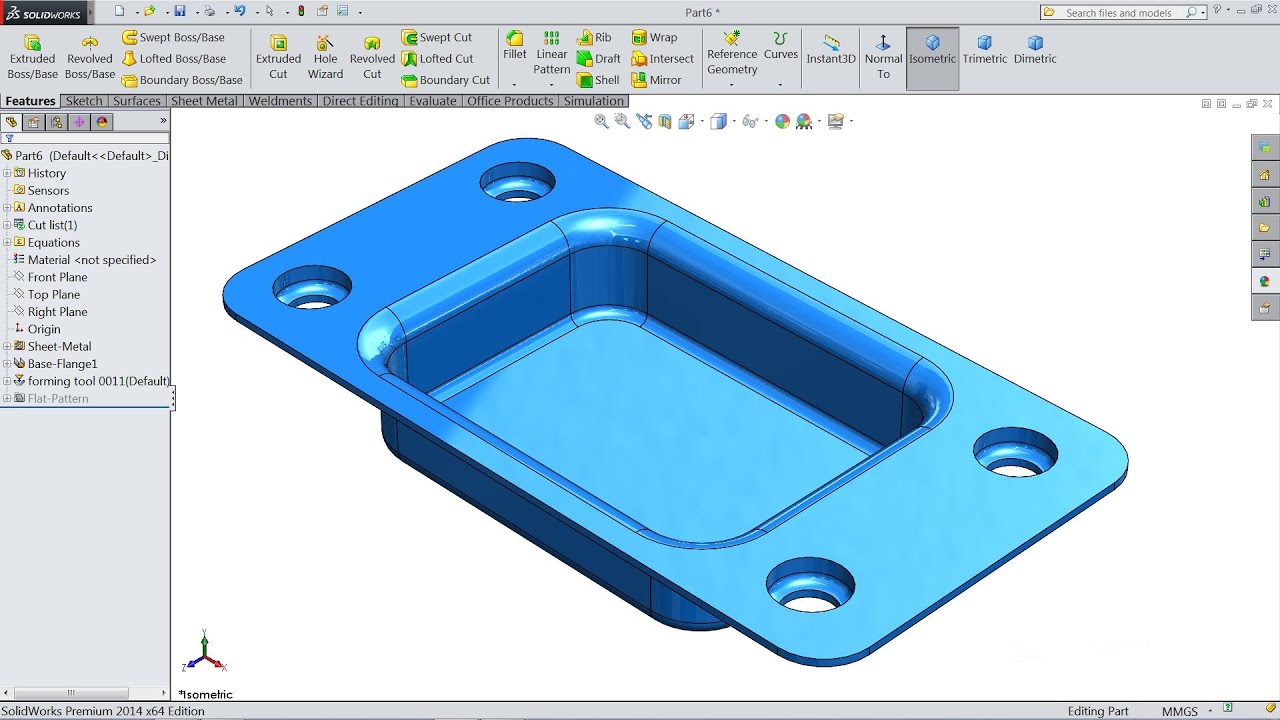

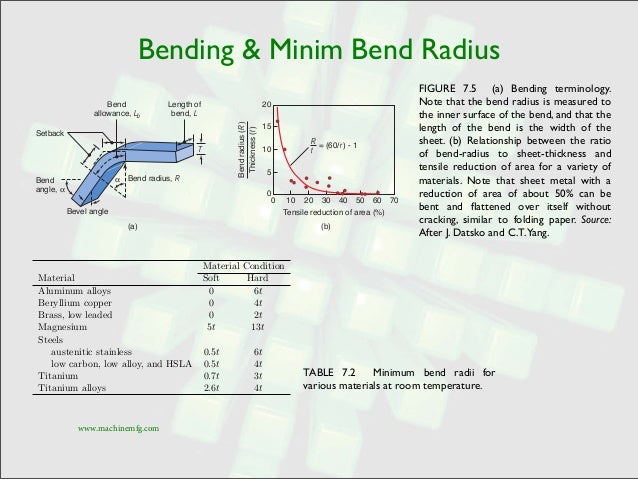

Bending test of sheet metal forming. Cooper sheet metal forming ch. Sheet metal bending bending of sheet metal is a common and vital process in manufacturing industry. Choose a bend radius that matches your minimum bend. I had a question on k factors for our 3 d modeling software.

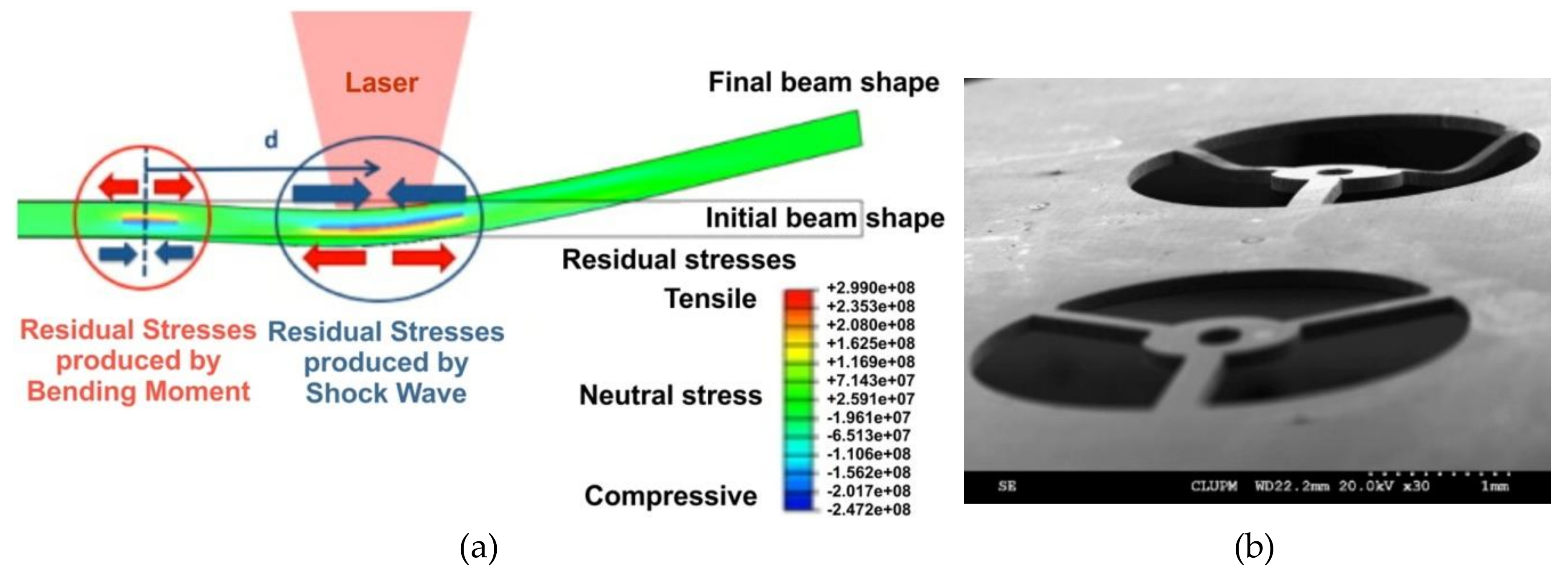

Stress distribution through the thickness of the part s s y y y y y elastic elastic plastic fully plastic moment m y b h 2 h 2 ybh2 4. Bending can be mentioned as press brake shaping as well. Forces needed to bend sheet metal. Tensile test ε1 2ε2 ε1 n.

Sheet metal forming 2 810 d. A cutout or the edge of your flange to your bend. Determine your minimum bend by measuring the distance from your closest feature i e. Press brake devices can be of a set of sizes generally from 20 up to 200 tons to meet particular riquirements.

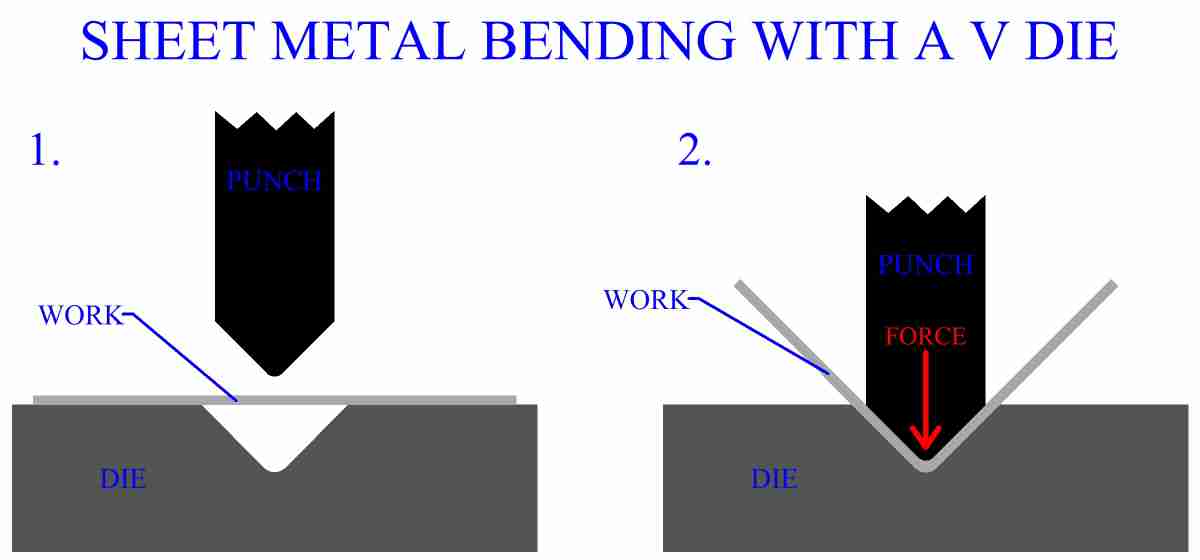

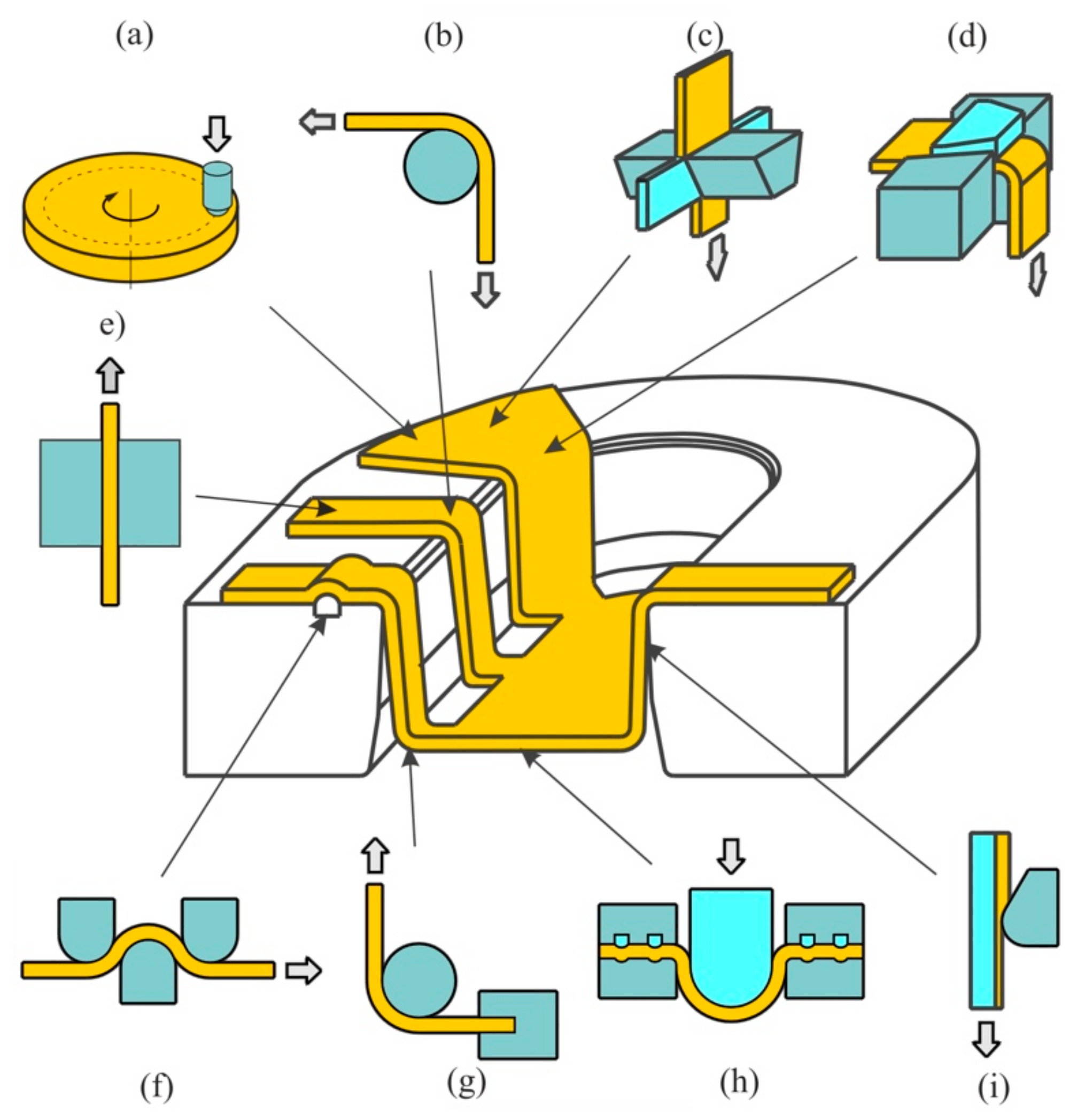

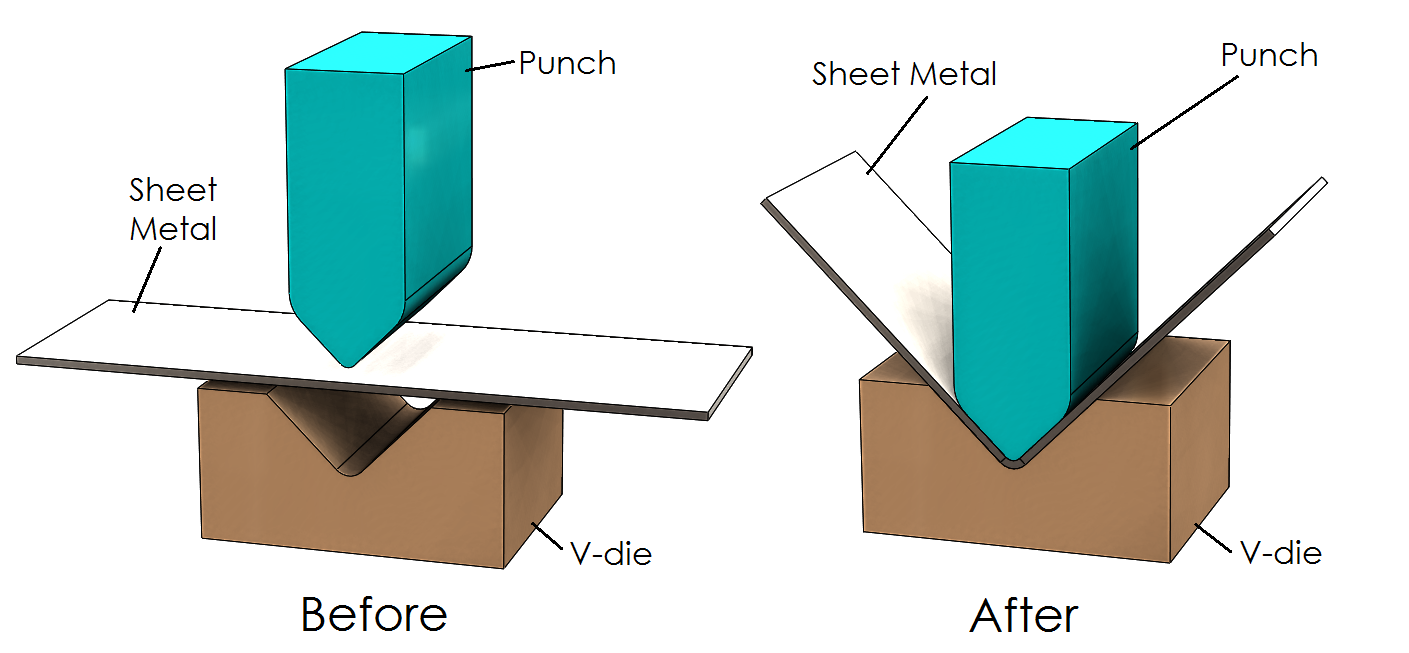

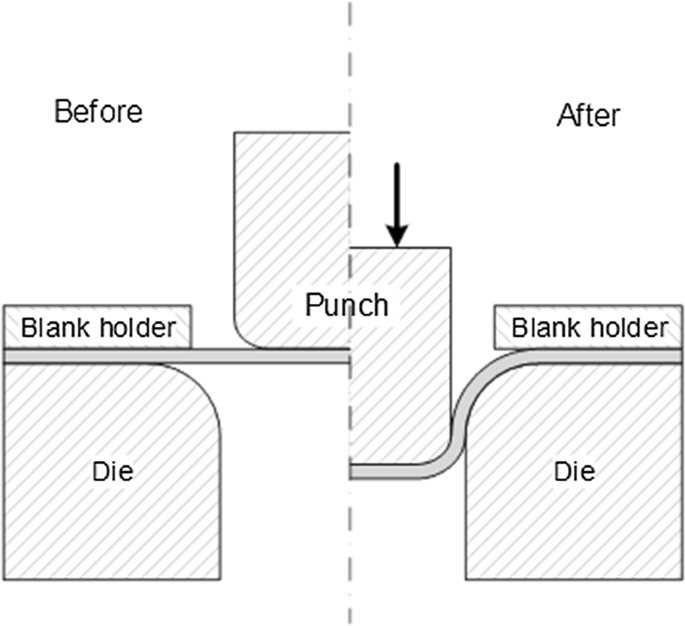

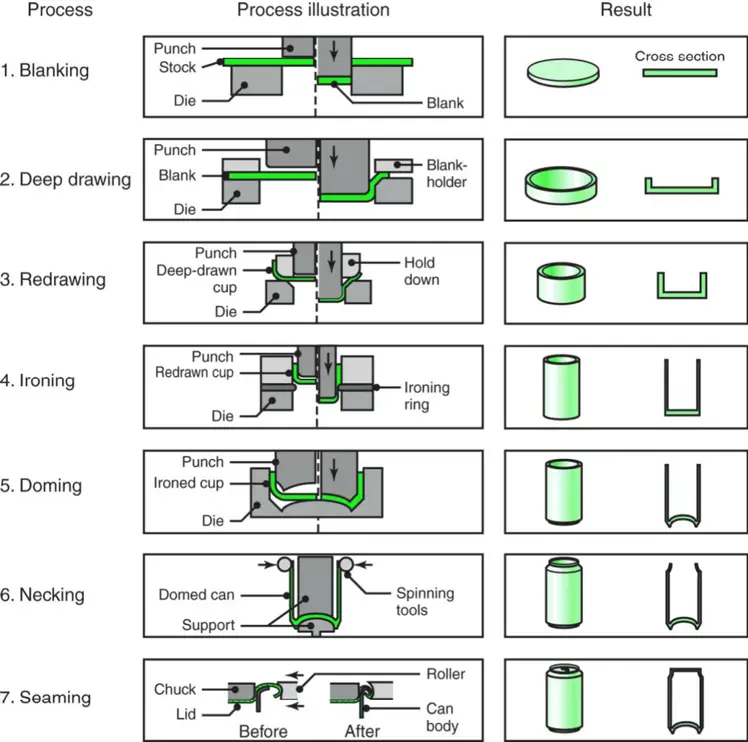

Sheet metal forming operations. Sheet metal bending is the plastic deformation of the work over an axis creating a change in the part s geometry. When sheet metal is bent it stretches in length. Similar to other metal forming processes bending changes the shape of the work piece while the volume of material will remain the.

The bend deduction is the amount the sheet metal will stretch when bent as measured from the outside edges of the bend. When you bend sheet metal the neutral axis shifts toward the inside surface of the bend. Bending of sheet metal quiz key. Here s a good rule of thumb for most materials.

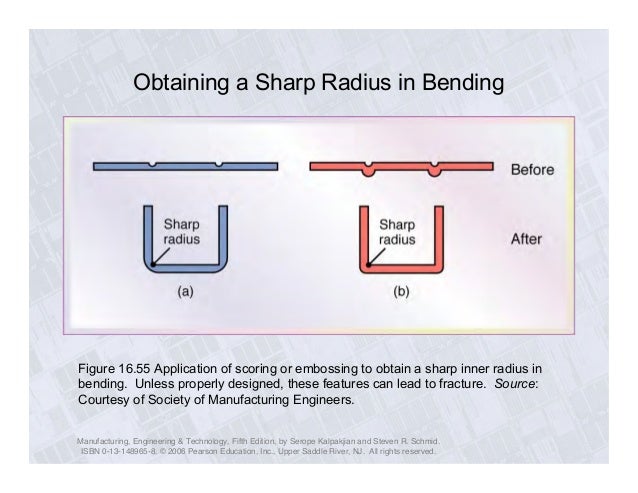

Sheet metal forming operations. The inside bend radius should be equal to the thickness of the material that you re forming. Metal folding is used to create many products including pipes enclosures boxes and more as sheet metal can be fashioned and reshaped in many ways such as rolling indenting bending and. Other sheet metal forming operations.

If you re bending 0 020 thick material use a 0 020 radius. In other words if you re bending 1 8 sheet use a tool with a 1 8 radius to form the inside of the bend. The amount of spring back is dependent on the material and the type of forming. These devices consist of top and bottom tools in the amongst of which plate metals can be placed.

Sheet metal forming operations. Bending of sheet metal quiz questions. Malleable material folded inside radius of the sheet thickness is doubled hard material is the radius of the inside corner of the bend is 3 times the thickness of the sheet 4. If the metal sheet has not been heat treated the thickness of the bend can be up to 50mm 2in.

Metal sheet is put upon a die and it is kept through the backside gauge. The formed bend radius is dependent upon the dies used the material properties and the material thickness. Sheet metal folding is the stage in the metal fabrication process and covers the bending folding and pressing of sheet metal into a predetermined geometry. Sheet metal forming operations.

Our design engineers typically use a factor of 0 4 for our air formed press brake parts. The k factor is the ratio of the neutral axis location t to the material thickness mt.