Benefits Ceramic Vs Metallic Brake Pads

Metal brake pads meanwhile are sometimes called metallic or sintered and you guessed it are made from metallic particles fused together.

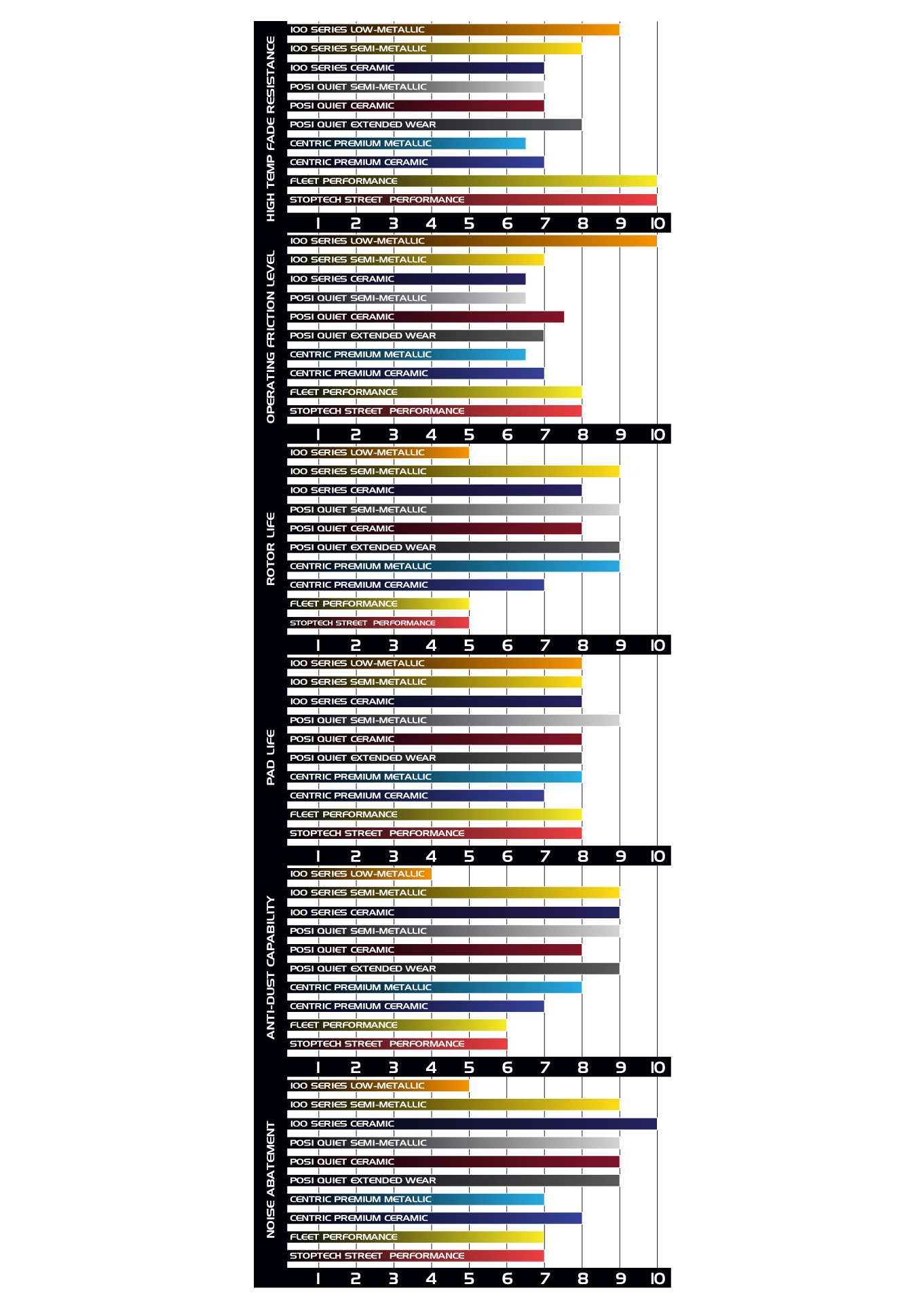

Benefits ceramic vs metallic brake pads. Carbon ceramic brake rotors offer tremendous heat dissipation benefits simultaneous with very low mass says ron younkin chevrolet s engineering manager of brakes rear wheel drive and. Ceramic vs semi metallic brake pads is the most controversial topic in the automotive world. Sintered pads are sometimes called metal or metallic. Ceramic will not stop as well as a good semi metallic pad.

For many drivers especially those who value high performance the choice between ceramic vs. Your vehicle needs to warm up some before you can take advantage of all of the benefits of this technology which means you ll spend more on fuel to achieve a similar performance. Their is no perfect brake pad for every rider or type of riding. There are some benefits to using ceramic brake pads as well as semi metallic brake pads but drawbacks exist in every situation.

Good meaning high cf or coefficient of friction. I design and test brakes for use on trailers for a living. Premium semi metallic pads provide a greater resistance to temperature fade compared to ceramic pads. Metallic brake pads are cheaper and more affordable than ceramic brake pads.

When you have ceramic brake pads equipped to your car then you might notice that they do not produce as much of a bite when compared to semi metallic pads. However semi metallic pads do create more dust than ceramic pads. They even do a better job of slowing down the vehicle because they are more aggressive against the brake discs. Metallic brake pads is easy.

Great thing about ceramic tho is it doesn t squeal usually and brake dust sticking to your wheels becomes non existant. Each of these three compounds has their own benefits and disadvantages. Ceramic brake pads are generally composed of dense ceramic material and embedded copper fibers. Because metals are such a good conductor of heat they tend to.

Performance driven drivers prefer the metallic brake pads because they offer improved braking performance in a much wider range of temperatures and conditions. Pros and cons to each compound. Low metallic has less than 30 percent metal by weight. Semi metallic pads normally contain more than 30 percent steel or iron by weight.

Metal brake pads are often used for oem spec meaning that s what you ll go home with if you buy a new bike from a bike shop. Organic pads are sometimes called resin. To understand the differences between the two types of brake pads you must first understand how they are constructed.