Benefits Of Ceramic Wheel Bearings

The price becomes a little more palatable when comparing the benefits it offers over more common and also expensive ceramic bearing pulley wheel upgrades but even the price of those is.

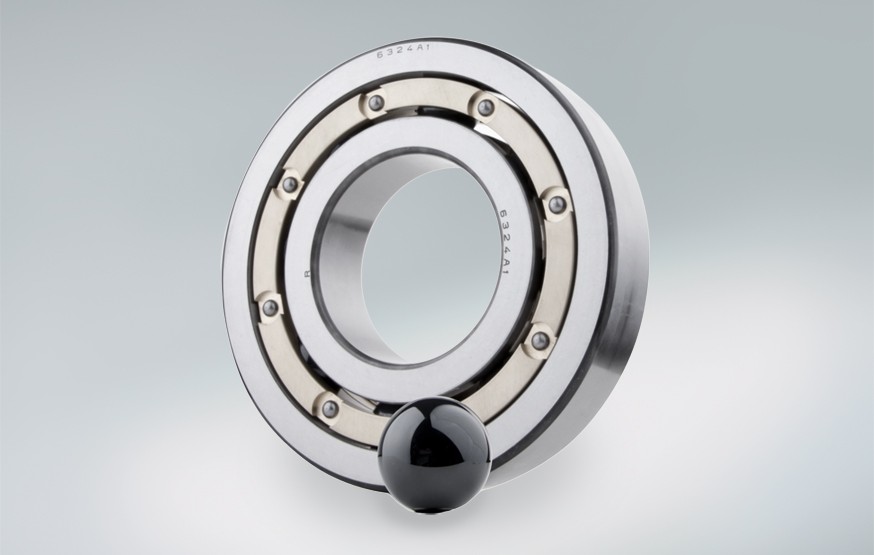

Benefits of ceramic wheel bearings. Leaving energy savings aside there are two other sections where the benefits of ceramic bearings are unquestionable. This atomic co operation yields a very strong attraction force and because of this ceramics offer a series of benefits in comparison to metals. Then you re racing with the lowest cost bearing available and not making use of the latest technology in bearings. All the tests i have seen test new or just broken in bearings and show that one could save somewhere between 5 and 10 watts for a pulley bottom bracket and wheel bearing upgrade of course mostly depending on your current set up as a starting point.

Bc forged wheels are among the leading wheel manufacturer when it comes to high end brands. Some people still believe the durability of ceramic bearings is bad some don t want to spend any money and some just want things to stay the way they always have been. Performance benefits of ceramic bearings high quality bearings save watts. Durability and peace of mind.

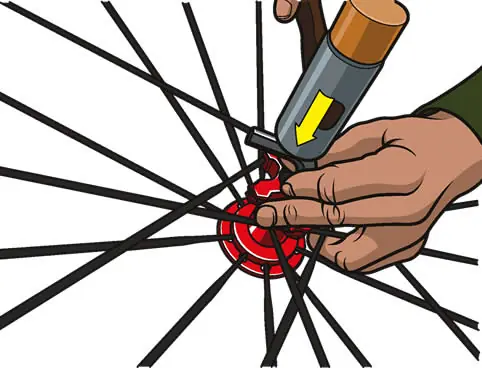

Recently we coated a set of brand new bc forged wheels with our ceramic layer. Ceramic bearings offer many benefits for the race with a low upgrade cost 520 466 9176 ultra low drag ceramic bearings for racing and industrial applications. A full set of cyclingceramic bearings starts at 80 and ceramicspeed wheel bearings cost from 240. Ceramic coating on new bc forged wheels.

Leading industry wheel dynamics expert and ceo of edco wheels paul lew backs this up and reckons it makes ceramic bearings a poor choice for hubs and headsets also adding that they offer no weight savings and are only beneficial in environments where high rpm revolutions per minute are required. You can find cheaper examples but cheaper types offer minimal gain over steel bearings. Here is an in depth look at how we got the job done. This means they share electrons.

For bottom bracket applications the maximum sustained rpm may be 130 explains lew. They normally have a very high hardness 70 90.