Bending 5mm Aluminium Sheet

This weakens the aluminium and creates a fracture line.

Bending 5mm aluminium sheet. Most frequently expensive sheet metal bending tools called brakes are used to bend sheet metal but you can also complete this task without one. The aluminum plate is too thick which exceeding the bending limit of the material. Theoretically aluminum sheet of any thickness can be bent and aluminum plate sheet 5mm belongs to a thick type of plates. 6061 t6 aluminum is tempered and notorious for not bending easily.

Flip the sheet over and repeat. Yes and many alloys of aluminum plate can be bent if you would like for the bending process has little to do with quality of a plate. Highly formable and one of the best kinds of aluminum to bend. Miserable to bend cracking is very common and cold bending will always weaken the metal.

Nalco recomends that a test bend is made prior to fabrication. The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius. Of course the bending effect is related to state of a plate. Most press brake tooling equiptment has been designed to bend steel rather than aluminium.

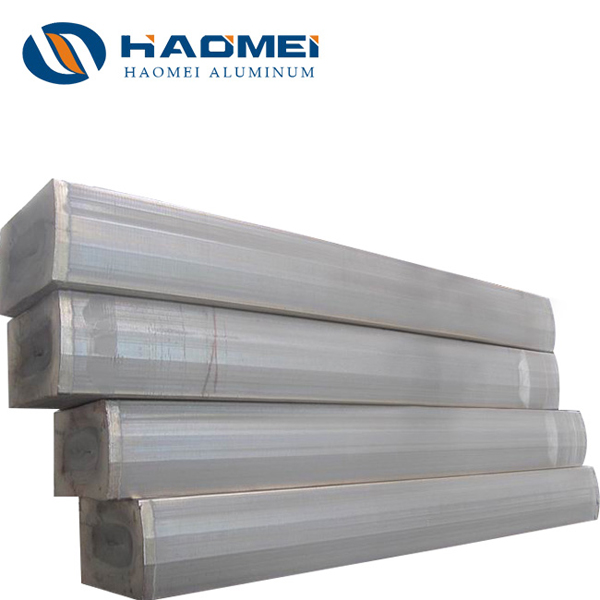

Material bend radii and minimum bend size charts please note. After a few wiggles the sheet will fracture along the cut line leaving a clean break as shown in the above photos. As a big aluminum sheet manufacturer haomei aluminum has different thicknesses of aluminum sheets. We re having trouble bending 6061 t6 aluminum without cracking and i was wondering if you could give us a few pointers.

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend. From a bending perspective it s always best to bend these parts in an annealed state and then temper them to the correct condition. The force must exceed the material s yield strength to achieve a plastic deformation. With the aid of a straight edge and a sharp knife score both sides of the aluminium sheet.

Can you bend aluminum plate sheet 5mm. Surface marking on the sheet from the bottom die v will indicate less than an optimal tooling configuration. Bending is one of the most common sheet metal fabrication operations. Steel has more elongation than aluminium enabling it to be stretched.

Place the fracture line over the edge of a table and bend the overhang slightly downwards. The 3003 aluminum sheet with o temper is better for bending. Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape. Welcome to inquire 5mm aluminium sheet price directly.